TLHAHISO MEKHOA

|

Setšoantšo sa No. |

Phallo ea metsi (Bokgoni) (T / h) |

Matla a Emulsifier (KW) |

Motor Speed (dagelever / mets) |

|

EA-165-QZ |

0.3-3 |

4 |

2800 RPM (RPM mefuta e mengata ea boikhethelo) |

|

EA-165-QZ |

03-5 |

5.5 |

|

|

EA-180-QZ |

1-6 |

7.5 |

|

|

EA-180-QZ |

1-8 |

11 |

|

|

EA-200-QZ |

1-10 |

15 |

|

|

EA-200-QZ |

1-12 |

18 |

|

|

EA-230-QZ |

2-15 |

25 |

|

|

EA-230-QZ |

2-20 |

30 |

* Tlhahisoleseling e kaholimo ke ea litšupiso feela 'me e ka fetoloa ho latela litlhoko tsa moreki. 'Sesebelisoa sena se ka fetoloa ho latela mofuta oa thepa e tala ho fihlela litlhoko tsa ts'ebetso, joalo ka viscosity e kholo, homogenization le litlhokahalo tse ling.

SEBOPEHO SEhlahisoa

E na le mesebetsi e mengata e ts'oanang le ho kopanya, ho hlohlelletsa, ho qhalanya, ho homogenizing, emulsifying, jj. E na le ts'ebetso e tsitsitseng le e ts'oanang, 'me e loketse haholo tlhahiso ea lihlahisoa tsa lebese, lino tse tahang, lijo le meriana. Ha ho na phofo, ha ho na likaroloana, ha ho na sebopeho sa clump.

Ho sebetsa hantle haholo: Ha ho bapisoa le ts'ebetso ea setso, e ka khutsufatsa nako ea ho sebetsa ka 80%, e ntlafatsa haholo ts'ebetso ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso. Ha e sebelisoe hohle meleng e tsoelang pele ea tlhahiso, empa hape le lits'ebetsong tse fapaneng tsa tlhahiso ea methapo, haholo-holo e loketseng viscosity e phahameng, lisebelisoa tse sa qhalaneng (viscosity ho fihlela 9O, 000mPas). Sesebelisoa ha se na lipheo tse shoeleng 'me se ka hlomelloa ka botlalo ka CIP / SIP, e fihlelang litlhokahalo le litekanyetso tsa bohloeki. Modular sebopeho: tšebeliso e tobileng ntle le on-site tlhomamiso le laele, haholo fokotsa ditjeo tlhomamiso. Sebopeho se kopaneng: ts'ebetso e nyane ea sebaka, ho bonolo ho e kopanya le lits'ebetso tse ling, ho boloka matsete.

MOKHATLO MOTLATSI

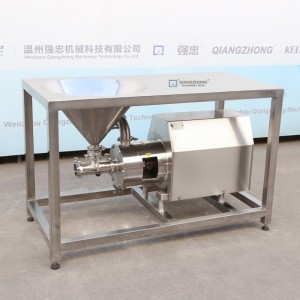

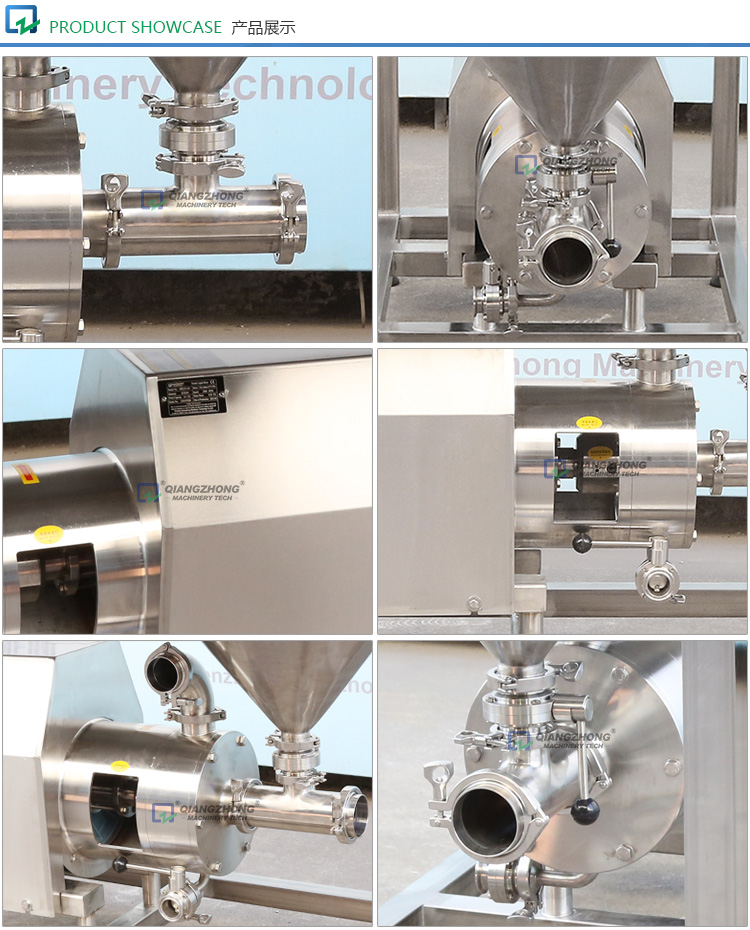

Sistimi ea mosebetsi: Sesebelisoa sa boikhethelo ke tšepe e sa hloekang SUS304 kapa 316L. Sistimi eohle ea lisebelisoa e batla e koetsoe, e hloekile, e hloekile, e bolokehile ebile e bonolo ho sebetsa.

Phepelo e ommeng ea phofo: Ke koung ea phepelo e bōpehileng joaloka V, e sebelisetsoang ho eketsa lintho tse tiileng tse nang le phofo e nang le sephahla se hloekileng, 'me mokhoa oa taolo ke oa matsoho kapa oa moea.

Khalase ea pono: (ka boikhethelo): Ho bonolo hore mokhanni a bone ka mokhoa o bonang boemo ba tšebetso ba sistimi eohle.

Sesebelisoa sa ho hlakola (ka boikhethelo): se sebelisetsoa ho hloekisa, ho qhala le ho etsa mohlala.

Moqapi o sebetsang hantle haholo: Ke karolo ea mantlha ea ts'ebetso ea sistimi. Sistimi ea rotor-stator e entsoeng ka bohlale e entsoe ka bohlale e etsa hore mochini o tsoakaneng o sebetsang hantle marang-rang o be le mesebetsi e fapaneng e ikhethang le e momahaneng. Li potoloha ka lebelo le phahameng haholo ha li kopana ka lebelo le phahameng mme ha li kopane ka kotloloho ho qoba ho tsofala. E bolela sebopeho sa pompo ea bohloeki ea centrifugal. Shaft ea pompo, tiiso ea mochini le lesale la tiiso kaofela ke thepa ea boleng bo holimo. Rotor, stator le cavity kaofela li entsoe ka tšepe e sa hloekeng e entsoeng ka tšepe e phahameng ka ho nepahetseng ea CNC. Sisteme e tsitsitse, e sebetsa hantle, e bolokehile ebile ea tšepahala.

Sistimi ea motlakase e sebetsang hantle haholo: Sistimi e matla ea lesale la mokelikeli ke karolo ea bohlokoa ea sistimi ho netefatsa hore sistimi e sebetsa hantle ebile e tsitsitse, e matla ebile e bolokehile. Sisteme e matla ea bohloeki e nang le bohloeki e fana ka matla a fetisisang bakeng sa sistimi eohle ea mixer le matla bakeng sa lisebelisoa tse tiileng. E amohela tšepe e se nang mokelikeli, e tšoarellang, e tsitsitseng ebile e ts'epahala. Sistimi ea ts'ireletso ea polokeho: Sisteme e na le tšepe e sa hloekeng e habeli ea ts'ireletso ea sefahleho ho qoba likaroloana tsa tšepe tse tiileng (linate, slag ea tšepe, likarolo tsa tšepe, lehlabathe, jj.) Ho senya sistimi.

Sistimi e sebetsang: Sistimi ea ts'ebetso e entsoe ka mokhoa o utloahalang, ka konopo e le 'ngoe ho qala kapa ho emisa ts'ebetso, mme liphoso li bonts'oa ka thoko. Ts'ebetso e bonolo le tlhokomelo e bonolo. E na le mesebetsi ea ts'ireletso joalo ka anti-overload, anti-short circuit, anti-phase loss le interactioning interaction ho thibela misoperation. E ka ba le sesebelisoa sa ts'ebetso e ikemetseng ka botlalo ho latela litlhoko tsa bareki.

Mofuta oa Stator / Rotor

Kabo e nyane ea boholo ba phatsa, ho tšoana ho phahameng

Ka sebaka se sekhutšoane, ts'ebetso ea phetiso e tlase

Khethollo ea liphapang tsa boleng lipakeng tsa lihlopha

Ho boloka nako, ho sebetsa hantle haholo, ho boloka matla

Lerata le tlaase le ts'ebetso e tsitsitseng

Ho bonolo ho e sebelisa, ho bonolo ho e hlokomela

E ka fihlela taolo e ikemetseng

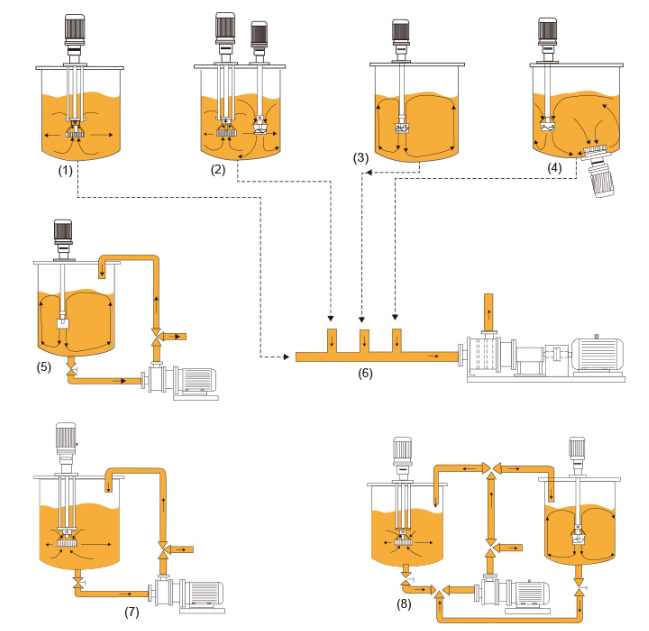

MOLAO-MOTHEO OA HO SEBETSA

Mohlahisi oa inthanete ea sebetsang hantle haholo ke moloko o mocha oa lisebelisoa tsa sistimi bakeng sa ho kopanya hantle lintho tse tiileng le maro, maro le maro. E na le sistimi e matla ea lesale la mokelikeli oa metsi ho netefatsa hore sistimi e sebetsa hantle ebile e bolokehile ebile ea tšepahala. E boetse e na le sete ea sistimi ea rotor-stator e entsoeng ka boqhetseke, e le hore sistimi e be le mesebetsi e fapaneng e ikhethang le e kopaneng. Tsamaisong e ikhethileng le e kopaneng ea sebopeho, lits'ebetso tsena tse peli lia sebelisana 'me li sebetsa' moho ho etsa lisebelisoa tse fapaneng kapele le ka mokhoa o ts'oanang homogenized le ho tsoakana sebakeng se senyane, ka tsela eo ho fumana sehlahisoa sa ho qetela se setle, se ts'oanang le se tsitsitseng.

SEBELISO

Indasteri ea lijo: homogenize lero la litholoana tse tsepamisitsoeng, lino tse telele tsa fiber, sopho, jeme e fapaneng, lero la litholoana, litapole tse khotliloeng, mahobe a mosetareta, jj .;

Lihlahisoa tsa lebese: homogenize lihlahisoa tsa lebese tse lomositsoeng: yoghurt e ntle, chisi e bonolo, botoro, jj.

Homogenize le kopanya lihlahisoa tsa lebese: joalo ka ice cream, lebese la chokolete, lebese la cocoa, CMC, starch, semela sa 'mela, jj.

Indasteri ea biomedicine: homogenate ea lisele, lisele tsa 'mele tse silafatsang, ente; lithibela-mafu; setlhare sa moriana; microcapsule emulsification;

Indasteri ea litlolo: emulsify litlolo tse fapaneng tsa sefahleho, litlolo tsa molomo, sesepa sa metsi, lintho tse hloekisang sefahleho, lihlahisoa tsa tlhokomelo ea letlalo, shampoo:

Indasteri ea lik'hemik'hale: lehoakhoa emulsification, surfactant, carbon ba batsho hasana; ho roala dae

Homogenize li-plasticizers tsa PVC: li-emulsions tse fapaneng, li-emulsions tsa fensetere, li-additives, jj. Indasteri ea peterolo: emulsify asphalt; asphalt e fetotsoeng; oli e boima; disele; setlolo; oli ea silicone, jj.

PONTS'O MOTLATSI

MEHATO YA TLHOKOMELO

PumpThe pompo ea emulsification e amohela sesebelisoa se entsoeng ka lebelo le phahameng haholo se kopaneng le stator. Tlas'a drive ya dilenaneo ho male rotor tlisa matla kinetic matla le lebelo le phahameng ka ho fetisisa mola le phello e phahameng-maqhubu phetha molao, e leng se etsang hore lintho tse bonahalang tse ho kuta, pepeta centrifugally, mokelikeli mokelikeli rubbed, tshusumetso le tabola lekhalo nepahetseng tsa stator le stator. Litholoana tse kopaneng tsa moferefere, jj., Ho fihlela sephetho sa ho hasana, ho sila, emulsification.

Ho latela litlhoko tse fapaneng tsa ts'ebetso, motsoako oa male rotor oa sethala le stator le sebopeho sa likarolo li ka hlophisoa. Mochini o tšoauoa ka palo e kholo ea ts'ebetso, tlhahiso e tsoelang pele ea inthanete, kabo e nyane ea boholo ba phatsa, ho tšoana hantle, matla a sebetsang hantle, lerata le tlase, ts'ebetso e tsitsitseng, mme ha ho na lipheletsong tse shoeleng, mme lisebelisoa li qhalakanngoa hantle ebile li kuta.

Tiiso ea mochini ke karolo e apereng eo bophelo ba eona ba ts'ebeletso bo amanang le maemo a ts'ebetso le tlhokomelo. Tiiso ea mochini mochini ke ho ts'epa lisebelisoa hore li pholile, ka hona ho thibetsoe ka tieo ho sebetsa haeba mochini oa tiiso o se na thepa, hore o se ke oa senya tiiso ea mochini. Ha seaplane e le sesebelisoa se tiisang, lintho tse ka phapusing e sebetsang li tlameha ho hloekisoa ka solvent kamora ts'ebeliso e ngoe le e ngoe.

Hlahloba hore na litiiso tsa pompo tsa keno le pompo li maemong a matle, le hore na maloanlahla, litšila tsa tšepe, kapa lisebelisoa tse ling tse ka senyang thepa li tsoakane le lisebelisoa. Hlahloba hore na mochini kaofela, haholo-holo enjene, o senyehile ha o tsamaisoa kapa o romelloa kantle.

Pele o hokahanya lesoba la thepa le sehokelo le phala ea ts'ebetso, phala ea ts'ebetso e tlameha ho hloekisoa. Kamora ho netefatsa hore phala ea ts'ebetso ha e na tšepe ea tšepe, li-chip tsa tšepe, likhalase tsa khalase, lehlabathe la quartz le lisebelisoa tse ling tse kotsi ho lisebelisoa, e ka hokahanngoa le mochini. Boemo ba ho kenya le setshelo li hlokahala hore li bolokoe ka mokhoa o otlolohileng. Boemo ba ho kenya bo lokela ho ema hantle ho setshelo. Haeba e kentsoe ka mokhoa o ts'oanelang, e tlameha ho koaloa hantle le ho sireletsoa khahlanong le mongobo, lerōle, mongobo le ho phatloha.

Pele o qala mochini, hokela metsi a pholileng a tiiso ea mochini. Ha u koala, tima motlakase ebe u khaola metsi a pholileng. Metsi a pholileng e ka ba metsi a pompo, 'me khatello ea metsi a pholileng ke <0.2Mpa. Matla a tlameha ho buloa kamora hore thepa e kene ka phapusing e sebetsang, mme mochini ha oa lokela ho sebetsoa ha ho se na thepa ho thibela tiiso ea mochini ho tuka ka lebaka la mocheso o phahameng kapa o amang bophelo ba ts'ebeletso.

Etsa bonnete ba hore tataiso ea potoloho ea dilenaneo e tsamaellana le tataiso ea potoloho e tšoailoeng ho sekontiri pele e bulela mochini, 'me koloi e thibetsoe ho sebetsa ka lehlakoreng le leng. Nakong ea ts'ebetso ea mochini, lisebelisoa tsa metsi li tlameha ho fepuoa khafetsa kapa ka bongata bo itseng ka setshelong. Mochini o lokela ho ba ntle ho idling ho qoba mocheso o phahameng kapa ho tiisa kristale ea thepa ka kamoreng e sebetsang le ho senya thepa.

Pompo e sebelisoa bakeng sa emulsification, homogenization le ho hasana ha lihlahisoa tlhahiso ea indasteri. Mochini o entsoe ka likarolo tse tharo kapa ho feta tsa li-rotor tse peli. Kamora hore thepa e kenngoe ka har'a rotor, e etsoa liketsong tse peli tsa ho kuta, 'me ea kuta, ea hasana le ho emulsified ka mekhahlelo e le hore mokelikeli oa multiphase o qhalane haholo mme likaroloana tse sa fetoheng li ntlafatsoe ka potlako.