Mekhahlelo ea Lihlahisoa

Sebopeho sa lihlahisoa

Vacuum emulsification e bolela hore high-shear emulsifier kapele le ka mokhoa o ts'oanang e aba mohato o le mong kapa ho feta mohatong o mong o tsoelang pele oa thepa e tlasa lephaka. Ka lebaka la matla a khenetiki a matla, lisebelisoa li mamella likere tse makholo a likete tsa haeteroliki ka motsotso lekhalong le lenyane lipakeng tsa stator le male rotor. Tlas'a ketso e kopaneng ea centrifugal extrusion, tšusumetso, ho taboha le moferefere, thepa e hasana mme e emulsified hanghang le ka mokhoa o ts'oanang. Kamora phetetso ea maqhubu a maqhubu a phahameng, lihlahisoa tse feliloeng tse se nang bubble, tse sa tieang le tse tsitsitseng boleng bo phahameng qetellong lia fumaneha.

Lisebelisoa tsa Sisteme

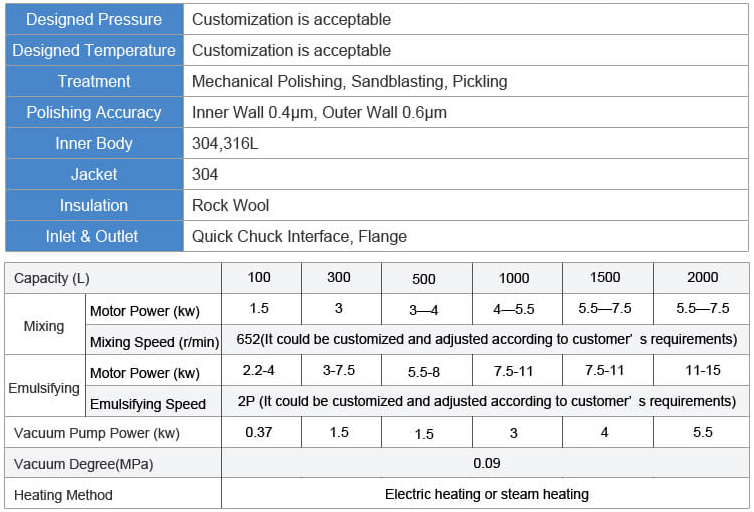

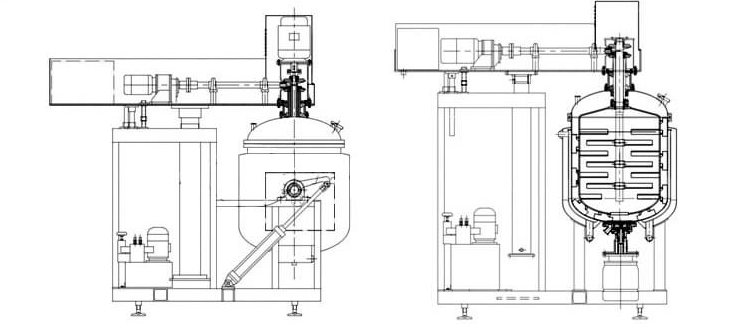

Vacuum Homogenizing Emulsification Tank e kenyelletsa tanka ea ho kopanya emulsification, sistimi ea vacuum, sistimi ea hydraulic, sistimi ea taolo ea motlakase le sethala sa tšebetso. Lisebelisoa tsa tanka ea ho kopanya e emulsification: mokelikeli o mokelikeli o nang le sefahleho sa lipeipi tse se nang tšepe, lesoba le tiileng, boema-kepe bo petelitsoeng, moea o kenang, ho phatloha ha lephaka, khalase ea pono, senotlolo sa mocheso, sesebelisoa sa CIP, sehokelo le lisebelisoa tse sa phefumoloheng tse nang le lerole.

Tloaelo Kopo

E loketse feela tlhahiso ea litlolo, joalo ka mafura, tranelate, mahe a linotsi a le mongobo le lihlahisoa tse ling, empa hape le tlhahiso ea lisebelisoa tse phahameng tsa viscosity liindastering tsa meriana, lijo, boenjiniere bo botle ba lik'hemik'hale, jj.

Likarolo tsa Sehlahisoa

● Karolo ea lisebelisoa tse kopaneng le lisebelisoa e entsoe ka SUS316L celik, ha ho na sekhutlo se shoeleng. Bobeli bokahare le kantle li pentiloe ka seiponeng, li kopana le maemo a GMP.

● Ho hlomelloa ka sistimi ea ho hloekisa CIP ho nolofatsa mokhoa oa ho hloekisa, ho etsa hore mosebetsi oa ho hloekisa o be bonolo le ho sebetsa hantle.

● Sistimi e kopanyang e amohela ho kopanya lehlakoreng le sekhahla le taolo ea maqhubu a lebelo la makoloi, e ka fihlelang litlhokahalo tsa tlhahiso ea lits'ebetso tse fapaneng.

● Ho hloekisa moea ho ka etsa hore thepa e fihlelle litlhoko tsa bohloeki, 'me ho ka fepa ho fepa, haholo-holo phofo e ka thibela lerōle le phaphametseng leholimong.

● Ho latela litlhokahalo tsa ts'ebetso, tanka e ka futhumatsa kapa ea pholisa thepa. Mokhoa oa ho futhumatsa e ka ba oa ho futhumatsa ka mouoane kapa ka motlakase ho latela litlhoko tsa bareki.

● Sistimi e tsoetseng pele ea taolo ea elektroniki e amohela taolo ea PLC mme e na le sekirini sa 'nete sa' mala ho lekola ka botlalo lintlha tse joalo ka mocheso oa thepa, ho tsukutleha le lebelo la homogenization, nako, jj. Ho fumana nako ea 'nete, ho rekota le ho hatisa lintlha tse amehang , mme e ka kenya le ho rekisa lintlha tse amehang.

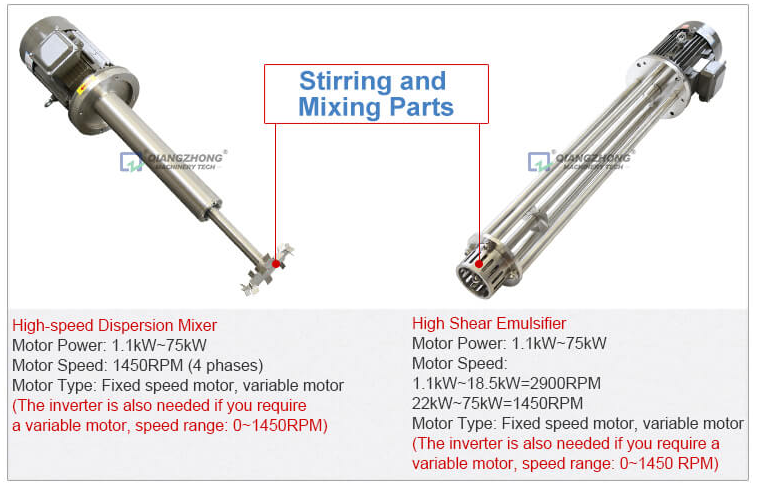

Mofuta oa Paddle o susumetsang

Sebopeho se Tloaelehileng sa Paddle e susumetsang

Re tla khetha mofuta o nepahetseng oa ho soka le lebelo le hlohlelletsang ho latela litšobotsi tsa thepa e tsoakoang le litlhokahalo tsa ts'ebetso ea mosebelisi.

Ntle le mefuta e boletsoeng kaholimo ea li-paddle tse ferehang, litanka tse ling tsa ho kopanya li kanna tsa ba le lisebelisoa tse phahameng tsa shear emulsifier kapa mofuta oa vane ea qhalakanyang mixer Matla a eona a matla a ho kopanya a ka qhalakanya le ho kopanya lisebelisoa kapele.