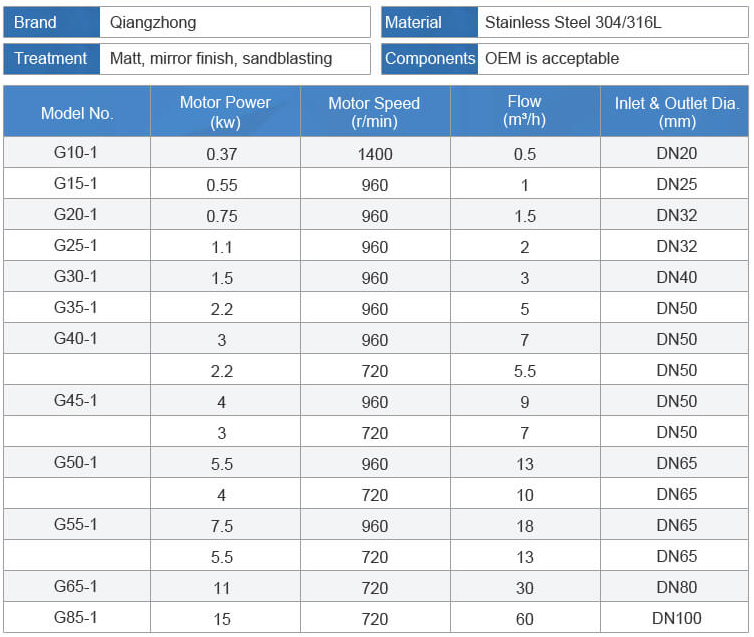

Mekhahlelo ea Lihlahisoa

Selelekela sa Sehlahisoa

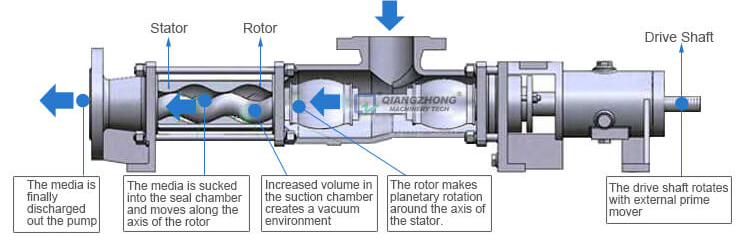

Pompo ea nsete e hula le ho tsoa mokelikeli ka ho potoloha ha screw. Sesepa se bohareng ke screw e sebetsang, e khannoang ke motsamaisi oa mantlha. Likurufu ka mahlakoreng ka bobeli ke lisurufu tse khannoang, 'me li potoloha ka morao le sekere se sebetsang. Likhoele tse sebetsang le tse khannoang li felile habeli. Ka lebaka la ho kenella hoa moea le ho lekana hantle ha moea le lebota le kahare la liner, ho theoa letoto la libaka tse ngata tse tiisitsoeng lipakeng tsa lesoba la ho hula le phallo ea pompo. Ka ho chenchana le ho kenella ha screw, sebaka se tiisitsoeng sa tiiso se theoa qetellong ea pompo, mokelikeli o ka kamoreng ea ho hula o koetsoe kahare ho ona, 'me o ntse o sutumetsoa haufi le kamore ea ho hula ho ea qetellong ea phallo ka lehlakoreng le tsamaeang la axial . E tšolla mokelikeli o kentsoeng libakeng tse arohaneng khafetsa ebile e le hantle, joalo ka ha eka linate li ntse li sutumetsoa pele ha moea o ntse o bilika. Ona ke molao-motheo oa mantlha oa ho sebetsa oa letoto lena la pompo e habeli ea screw.

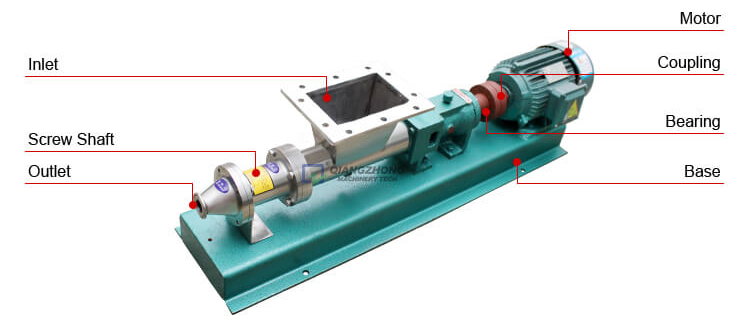

Likarolo tsa Pump:

1. Mohala o tiisitsoeng ka moea o kopaneng le male rotor oa stator o arola ka ho felletseng kamore ea ho hula ho tsoa phapusing ea phallo, e le hore pompo e sebetse hantle joalo ka sephahla;

2. E ka tsamaisa mecha ea litaba e mekhahlelo e mengata ea mokelikeli, khase le ho tiea.

3. Molumo ha o fetohe ha mokelikeli o ka har'a pompo o phalla, ha ho na pherekano e ferekanyang le pulsation;

4. Kamore ea bophahamo ba modumo e entsoeng ka "stator" ea "elastic" e ka fokotsa ho senyeha ha sekhahla se nang le likaroloana tse thata;

5. Motsoako oa viscosity ea mahareng o fihla ho 50,000Mpa · s, lintho tse tiileng tse ka bang 50%;

6. Sekhahla sa phallo se lekana le lebelo, mme ka 'musisi, e ka fetola phallo ka boiketsetso,' me ho tsamaisa pele le morao ho lumelloa.

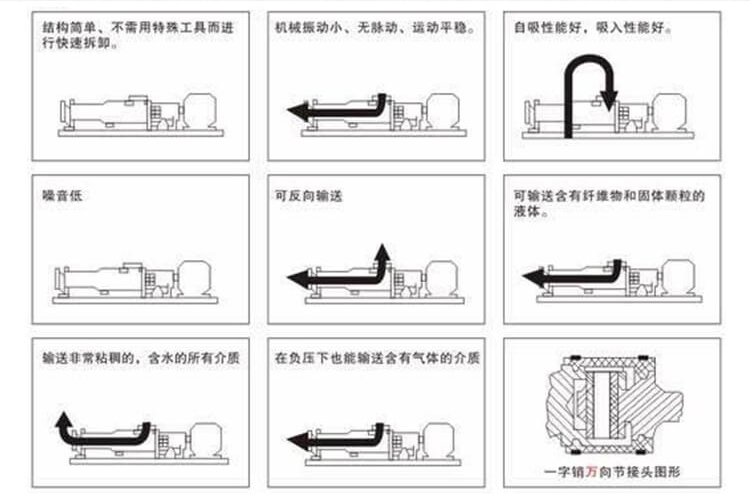

Pompo ea screw e na le melemo e latelang:

● Ha e bapisoa le pompo ea centrifugal, pompo ea screw ha e hloke ho kenya valve, 'me sekhahla sa phallo ke phallo e tsitsitseng e tsitsitseng;

● Ha e bapisoa le pompo ea plunger, pompo ea screw e na le bokhoni bo matla ba ho itlhahisa le bophahamo bo phahameng ba ho hula;

● Ha e bapisoa le pompo ea diaphragm, pompo ea screw e tsamaisa mefuta eohle ea litšila tse kopaneng, joalo ka mahareng a nang le khase le likaroloana tse thata kapa likhoele, hape e ka tsamaisa lintho tse fapaneng tse senyang;

● Ha li bapisoa le lipompo tsa lipeipi, lipompo tsa sekoti li ka tsamaisa mecha ea litaba e matla haholo;

● Ho fapana le lipompo tsa piston, lipompo tsa diaphragm le lipompo tsa gear, lipompo tsa screw li ka sebelisoa bakeng sa ho tlatsa le ho metering meriana.

Ho sebetsa Molao-motheo

Pompo ea screw ke pompo ea mofuta oa push-type. Likarolo tse kholo ke male rotor le stator. Rotor ke lead e kholo-e kholo, leino le leholo, le sekhahla se sephara sa hare-helix, 'me stator e ts'oaroa ka letsoho le matsoho, e etsang sebaka sa sebaka sa polokelo lipakeng tsa male rotor le stator. . Ha male rotor e sebetsa ho stator, seaplane se tsamaea ka axial ho tloha pheletsong ea ho hula ho fihlela motsamao o tsoang.

Pompo ea screw e na le melemo e latelang:

1.A mefuta e fapaneng khatello ea le phallo. Khatello e ka ba 3.4-340 kgf / cm² mme sekhahla sa phallo ke 1,8600 cm³ / m;

2. Mefuta e mengata e fapaneng le li-viscosities tsa maro a phepeloang;

3. E na le lebelo le phahameng ka lebaka la matla a tlase a inertia a likarolo tse potolohang pompong

4. Ka bokhoni ba boithati, ts'ebetso e ntle ea ho hula ,;

5. Phallo e ts'oanang, thothomelo e tlase, lerata le tlase;

6. Ha e nahane hakaalo ka khase le mobu o kenang ha o bapisoa le lipompo tse ling tsa rotary,

7. Sebopeho se tiileng, ho kenya habonolo le tlhokomelo.

The bozangi litomba pompo nsete ke hore nsete hloka sebetsa phahameng le kopano; Ts'ebetso ea pompo e nahanela liphetoho ho phallo ea mokelikeli.

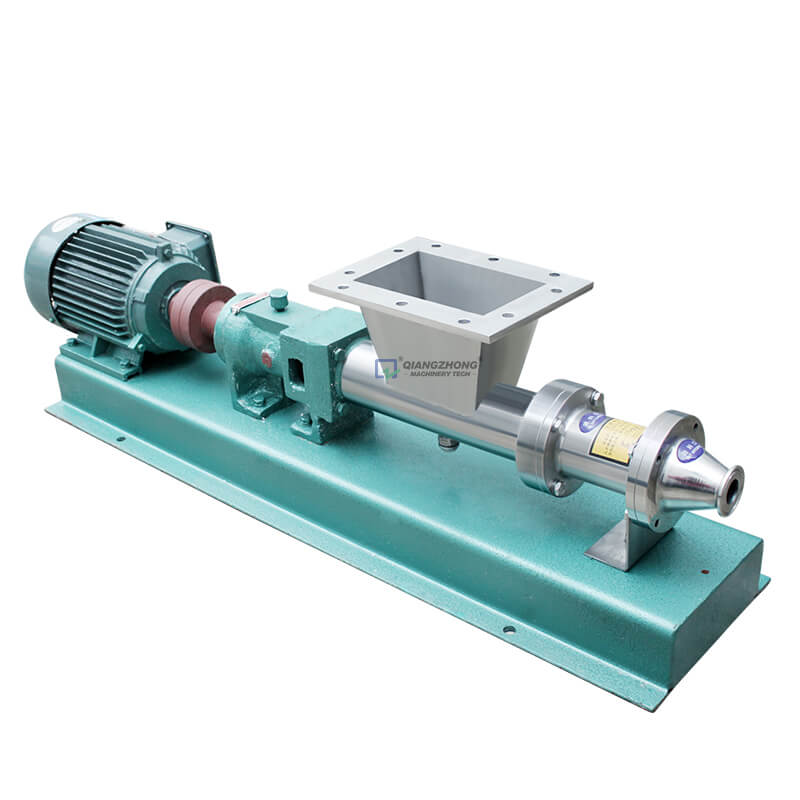

Pontšo ea lihlahisoa

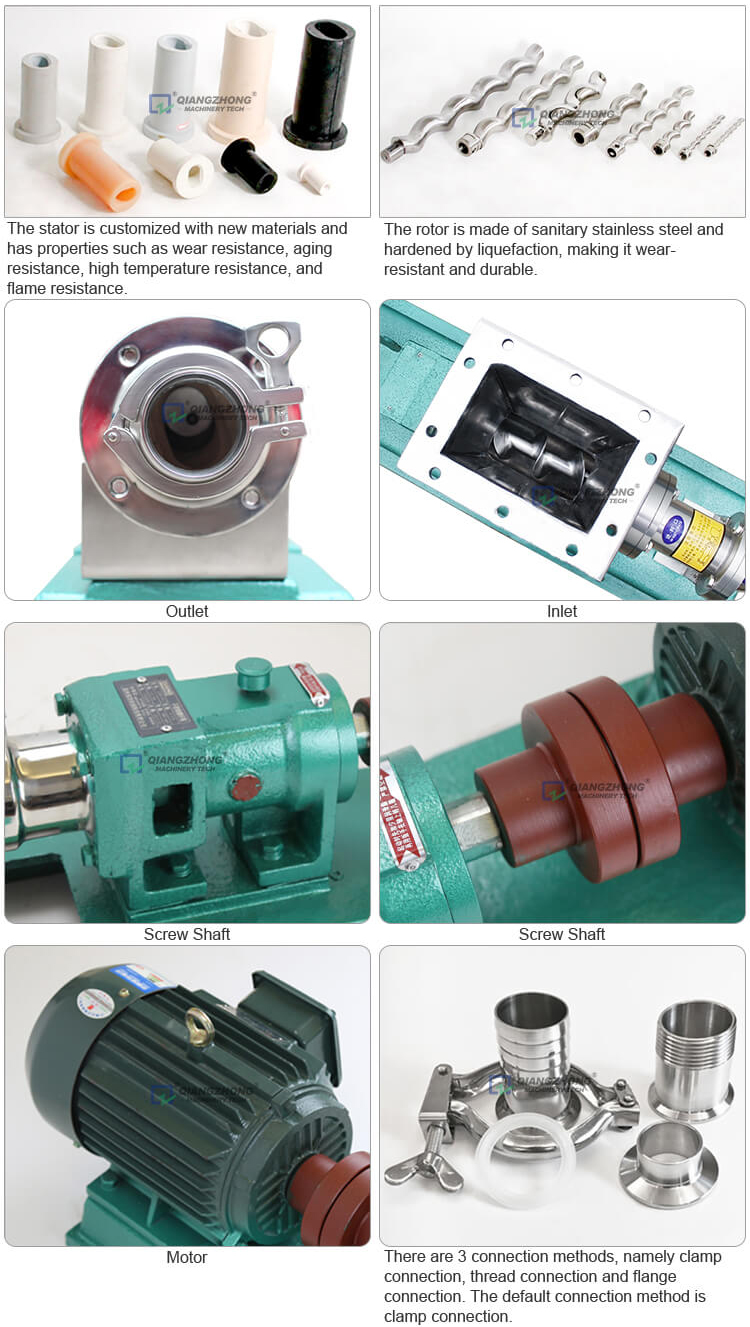

Stator e hlophisitsoe ka thepa e ncha ebile e na le litšobotsi tse kang ho itšireletsa, ho tsofala, ho hanyetsa mocheso o phahameng le ho hanyetsa lelakabe.

Rotor e entsoe ka tšepe e sa hloekang e hloekileng ebile e thatafalitsoe ke ho qhibiliha, ho e etsa hore e hanele ebile e tšoarelle.

Ho na le mekhoa e meraro ea khokelo, e leng khokahano ea ts'oarello, khokahano ea khoele le khokahano ea flange. Mokhoa o ikhethileng oa khokahano ke ho hokahanya ha clamp.

Liphoso tse tloaelehileng le tharollo

1.Pompo ha e sebetse:

Lisosa tse ka bang teng: Rotor le stator li thata haholo; motlakase o tlase haholo; viscosity ea seaplane e phahame haholo.

Tharollo: Fetola pompo makhetlo a 'maloa ka lisebelisoa le ka matla a basebetsi; fetola khatello; hlapolla mecha ea litaba.

Pompo ha e tsoe:

Lisosa tse ka bang teng: tsela e fosahetseng ea ho potoloha; mathata ka tube ea ho hula; phahameng haholo e tiileng e qamathelang mahareng; li-rotor, stator, kapa likarolo tsa phetisetso li senyehile;

Tharollo: Fetola tataiso ea chenchana; hlahloba ho lutla, li-valve tse bulehileng le li-valve; hlapolla media; lekola le ho khutlisa likarolo tse senyehileng;

Ho hloka phallo:

Lisosa tse ka bang teng: lipeipi tse dutlang; li-valve tse sa bulehang ka botlalo kapa tse sa koaloang ka mokhoa o itseng; lebelo le tlaase la ho sebetsa; ho roala li-rotor le li-stators.

Tharollo: Hlahloba le ho lokisa lipeipi; bula liheke tsohle, tlosa lipolaka; fetola lebelo; tlosa dikarolo tse senyehileng

4.Lack la khatello ea:

Lisosa tse ka bang teng: Rotor e tsofetseng le stator.

Tharollo: Tlosa rotor, stator

Ho chesa mocheso oa 5.Motor:

Lisosa tse ka bang teng: ho hloleha ha makoloi; khatello e feteletseng ea ntlo, tšenyo ea likoloi le tšenyo ea likoloi.

Tharollo: Hlahloba enjene le ho e rarolla; fetola khatello ea phetoho ea li-valve; nka sebaka sa karolo e senyehileng.

Khatello ea metsi e theoha haholo:

Lisosa tse ka bang teng: Ho thiba ha potoloho ka tšohanyetso kapa ho dutla ha potoloho; stator e tebileng; phetoho ea tšohanyetso mokelikeling oa mokelikeli; lerotholi la tšohanyetso la motlakase.

Tharollo: Tlosa tubing e kengoeng kapa e koetsoeng; nka sebaka sa stator rabara; fetola mokelikeli oa viscosity kapa motlakase oa motlakase; fetola voltage.

7. Palo e kholo ea mokelikeli o dutlang selomong sa shaft:

Lisosa tse ka bang teng: ho apara ha bonolo

Tharollo: Tobetsa kapa kenya sebaka tlatsong.

Litaelo tsa ho kenya

● Ela hloko tsela eo motlakase o potolohang ka eona ho thibela ho potoloha ho hoholo.

● Phala e tlosoang habonolo e bolelele bo batlang bo le boholo bo nyane ho stator e lokela ho hlongoa pele ho moo metsi a tsoang teng ho nolofalletsa stator e ncha.

● Boloka pompo e kenelletseng ka nqa e le 'ngoe, sehokelo ka lehlakoreng le otlolohileng, hore tiiso e sebetse maemong a khatello, e fokotsa khatello ea kamore e tiisitsoeng. Potoloho: ho potoloha ka lehlakoreng le leng ho ea ka lehlakoreng le leng ho tloha ha u tsoa. Pipe e lokela ho hlophisoa ho ts'ehetsa lintlha, hobane pompo ea pompo le li-flanges (liphaephe) tsa pompo ha li khone ho mamella boima ba phala.

● Phala e lokela ho hloekisoa pele e kengooa ho thibela lintho tsa kantle ho naha ho senya stator le male rotor le ho baka ho koala.

● Bophara ba lipeipi bo lokela ho tsamaellana le bophara ba pompo ka hohle kamoo ho ka khonehang. Bophara bo nyane haholo ba lesoba bo ka baka phepelo e sa lekaneng ea pompo, e tla ama pompo le khatello ea khumo. Maemong a boima, e tla lebisa ho sisinyeheng ha lipeipi le tšenyo ea pele ea stator. Bophahamo ba lipeipi tse nyane haholo bo tla baka tahlehelo ea khatello ea sehokelo.

● Bakeng sa litiiso tsa shaft tse nang le litiiso tsa mochini, eketsa metsi a hloekileng, oli e tlotsang kapa sehatsetsi se seng.

Bakeng sa litiiso tsa shaft tse tiisitsoeng ka nako e le 'ngoe, haeba maqhubu a fanoa e le maqhubu a matla, a tiileng habonolo le a kristale, tiiso ea mochini e lokela ho hloekisoa kamora pompo e emisa ho sebetsa ho netefatsa ts'ebetso e tloaelehileng ea tiiso ea mochini. Lehlakore le leng le le leng la lebokose la tiiso le na le sehokelo sa phala ea lipeipi tsa lisenthimithara, 'me sehlahisoa se kopanyang se kentsoe. Mohala oa ho kenella oa mokelikeli o tsamaeang ka kotloloho o hokahane le lebokose la tiiso. Ka lehlakoreng la eona la sehokelo, ho koaloa hoa ntlo (e leng habohlokoa bakeng sa ho boloka khatello e itseng ka lebokoseng la sealability) e hokeloa moleng oa kantle. Ha o qala mochini, mokelikeli o potang o lokela ho qalisoa pele, ebe o bula pompo; ha e emisoa, pompo e lokela ho emisoa pele, ebe e tima mokelikeli o potolohang.