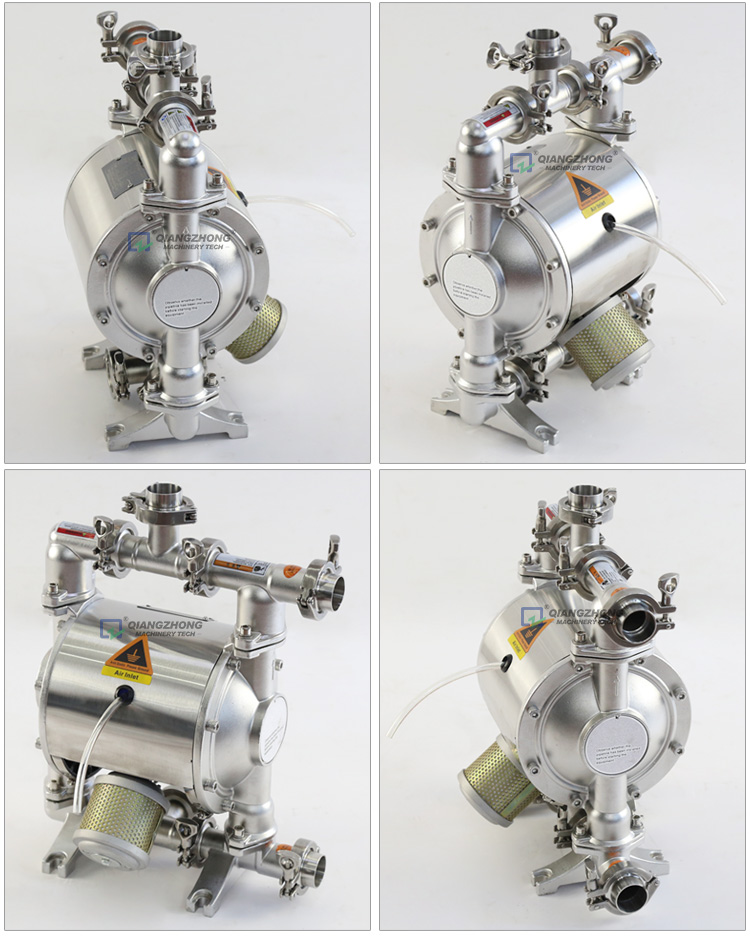

Bohloeki pneumatici diaphragm di-pump

E sebelisoa liketsahalong tse fapaneng tse ikhethang ho fihlela litlhoko tsa basebelisi ba fapaneng E sebelisoa ho pompa media o ke keng oa pompeloa ke lipompo tse tloaelehileng le ho fihlela litholoana tse khotsofatsang.

Mekhahlelo ea Lihlahisoa

| Setšoantšo sa No. |

Phalla (T / h) |

Dia. (limilimithara) |

Phahamisa (limithara) |

Ho hula (limithara) |

Khatello ea Moea o Sebelisang Partical Dia. |

boima ba 'mele (kg) |

||

|

(mpa) |

(scfm) |

(limilimithara) | ||||||

| QBSY5-20 | 0.1-1.8 |

20 |

0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-25 | 0.1-1.8 | 25 | 0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-32 | 0.1-6 | 32 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-38 | 0.1-6 | 38 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-51 | 0.1-12 | 51 | 0-50 | 5.48 |

0.75 |

32 |

5.5 |

33 |

| QBSY5-63 | 0.1-12 | 63 | 0-50 | 5.48 |

0.75 |

12.7 |

5.5 |

33 |

| QBSY5-76 | 0.1-22 |

76 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

| QBSY5-89 | 0.1-22 |

89 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

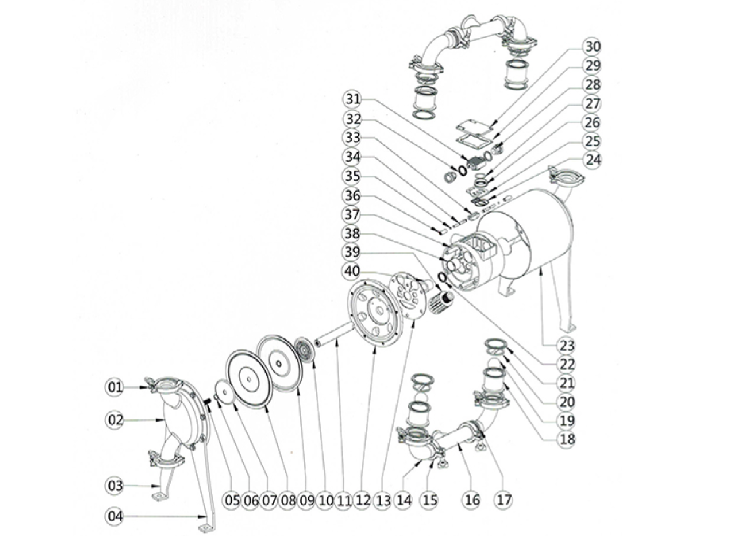

| 1. B Mofuta oa Clamp | 11. Ho kopanya Rod Shaft | 21. Tiiso ea BType | 31. Likarolo tse kholo tsa Slider Aluminium |

| 2. Kholomo | 12. Melao | 22. V-Ring | 32. V Ring |

| 3. Leoto le letšehali | 13. Khase ea Valve ea Khase Gasket | 23. Sekoahelo se Sireletsang | 33. Slider se senyane |

| 4. Leoto le letona | 14. Ho kenya ka potlako | 24. Tataisa Block Gasket | 34. Thuso e matlafatsang |

| 5. Lisebelisoa tsa Plywood | 15. Mofuta oa Clamp | 25. Buka ea Tataiso | 35. Ho matlafatsa Rod O-Ring |

| 6. O-Ring e petsoha | 16.Pipe ea Outlet le Outlet | 26. Likarolo tse kholo tsa Slide Plastic | 36. Ho Sebelisa Sekoaelo sa Rod |

| 7. Splint ea kantle | 17. Mofuta oa Tiiso ea Mofuta | 27. Slider e kholo O-Ring | 37. Kamore ea Valve |

| 8. Lera la PTFE | 18. Ball belofo | 28. Likotopo | 38. Sleeve ea Piston |

| 9. Filimi ea Poly | 19. Ball belofo | 29. Sekoahelo sa Valve ea Khase | 39. Silencer |

| 10. Splint ea ka hare | 20. Sekoahelo sa Setulo sa Ball | 30. Sekoahelo sa Valve | 40. Ho kopanya Rod Sleeve |

Ho sebetsa Molao-motheo

Pneumatici diaphragm pompo ke pompo ea volumetric e tlisang phetoho ea molumo ka ho khutlisa phetoho ea moferefere. Molao-motheo oa eona o sebetsang o ts'oana le pompo ea plunger. Lipompo tsa diaphragm li na le likarolo tse latelang:

I Pompo e ke ke ea chesoa haholo: Ka moea o petelitsoeng joalo ka matla, ho qeta ke mokhoa oa ho holisa le ho monya mocheso, ka hona nakong ea ts'ebetso, mocheso oa pompo ka boeona oa fokotseha mme ha ho na khase e kotsi e tsoang.

2-Ha ho na moloko oa tlhase: Lipompo tsa pneumatic diaphragm ha li sebelise matla a motlakase joalo ka mohloli oa matla ebile li ka thibela litlhase tsa motlakase kamora hore li thehoe.

3.lt e ka feta mokelikeli o nang le likaroloana: Hobane e sebelisa mokhoa o sebetsang oa volumetric mme lesoba ke valve ea bolo, ha ho bonolo ho koaloa.

4. Matla a ho kuta a tlase haholo: thepa e lokolloa boemong bo ts'oanang le ha e huloa ha pompo e le mosebetsing, ka hona ho tsukutleha ha thepa ho nyane mme ho loketse ho fetisa lintho tse sa tsitsang.

5. Sekhahla se fetolehang sa phallo: Ho ka kengoa belofo e kobehang setsing sa thepa ho laola phallo.

Mosebetsi oa boithaopo.

E ka ba ea idling ntle le kotsi.

8.lt e ka sebetsa ho qoela.

9. Mefuta e mengata ea maro e ka tlisoang e pharalletse haholo ho tloha ho e tlase haholo ho isa ho e phahameng haholo, ho tloha ho ts'enyeho ho isa ho e nyarosang.

10. Sisteme ea taolo e bonolo ebile ha e rarahane, ntle le likhoele, fuse, jj.

II Boholo bo bonyenyane, boima bo bobebe, bo bonolo ho tsamaisoa.

12.Lubrication ha e ea hlokahala, ka hona tlhokomelo e bonolo ebile ha e bake tšilafalo ea tikoloho e sebetsang ka lebaka la ho rotha.

13.lt e ka lula e sebetsa hantle, 'me e ke ke ea fokotsa ts'ebetso ea mosebetsi ka lebaka la ho tsofala.

Ts'ebeliso ea eneji ea 14.100%. Ha sehokelo se koetsoe, pompo e emisa ka bo eona ho thibela ho sisinyeha ha lisebelisoa, ho roala, ho tlala le ho hlahisa mocheso.

Ha ho na tiiso e matla, tlhokomelo e bonolo, ho lutla ho qojoa, 'me ha ho na ntlha e shoeleng ha u sebetsa.