TLHAHISO MEKHOA

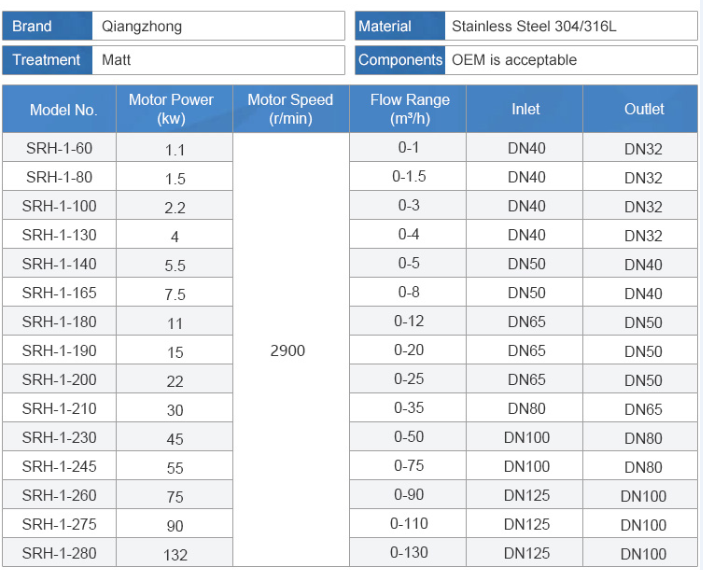

* Tlhahisoleseling e kaholimo ke ea litšupiso feela 'me e ka fetoloa ho latela litlhoko tsa moreki. 'Sesebelisoa sena se ka fetoloa ho latela mofuta oa thepa e tala ho fihlela litlhoko tsa ts'ebetso, joalo ka viscosity e kholo, homogenization le litlhokahalo tse ling.

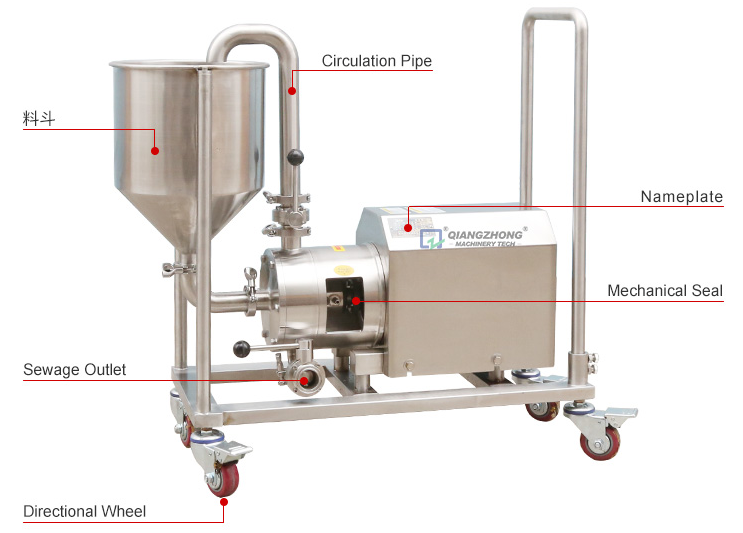

SEBOPEHO SEhlahisoa

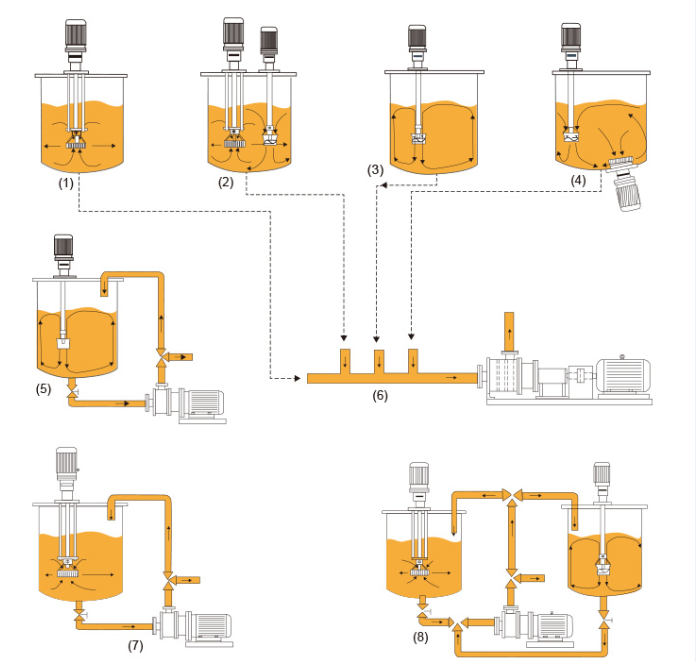

Pompo ea emulsification (eo hape e bitsoang in-line high-shear hasanya mixer) ke sesebelisoa se tsoakiloeng hantle se sebetsang hantle se kopanyang ho hasanya, ho qhalakanya, ho sithabetsa, ho qhibiliha, hantle, ho theola moea, homogenization le emulsification, eo likarolo tsa eona tsa ts'ebetso e leng stator le rotator, Rotor e potoloha ka potlako ho hlahisa matla a centrifugal le matla a hydraulic mme stator e lula e eme. Ka motsoako o nepahetseng oa male rotor le stator, matla a ho kuta a maholo a hlahisoa nakong ea potoloho e lebelo haholo, 'me thepa e beoa ka shear e matla, centrifugal extrusion, ho phatloha hoa tšusumetso, khohlano ea metsi le moferefere o tšoanang. Kahoo, mecha ea phatlalatso e fapaneng joalo ka karolo e sa bonahaleng e sa fetoheng, mokelikeli oa metsi le mochini oa khase li qhalakane ka mokhoa o ts'oanang le hantle ebile li emulsified hanghang. Kamora potoloho e khutlisetsang, sehlahisoa se tsitsitseng le sa boleng bo phahameng se qetella se fumanoe.

Pompo ea emulsification / in-line high-shear dispersion mixer e ka tsamaisa sekhahla se le seng kapa tse 'maloa molemong o mong o tsoelang pele, ha maemong a tloaelehileng mekhahlelo e sa ts'ehe. Ka sekhahla se phahameng sa shear se hlahisoang ke lebelo le phahameng la rotor le matla a phahameng a kinetic a tlisoang ke phello e phahameng ea maqhubu, thepa e lekhalong le moqotetsane oa male rotor le stator e qobelloa ke shear e matla ea mochini le ea haeteroliki, centrifugal extrusion, mokelikeli oa mokelikeli khohlano, tšusumetso ea meokho le pherekano le litlamorao tse ling tse felletseng Seo se etsa hore mohato o tiileng o sa lumellaneng, mohato oa mokelikeli le mochini oa khase hanghang o homogenized, o qhalakantsoeng le ho emulsified tlasa ketso e kopaneng ea mahlale a holileng a lekanang le bongata ba litlatsetso. Qetellong lihlahisoa tse tsitsitseng le tsa boleng bo holimo lia fumaneha kamora makhetlo a mangata a maqhubu a phahameng.

Lihlopheng tse sebetsang tsa pompo ea emulsification ho kentsoe lihlopha tse tharo tsa stator le male rotor. Phetiso theko ka kamoreng sebetsa e cantilevered. Khokahano ea rekere e hokahanya enjene le sekontiri se ka matlong a behang ho ntlafatsa boleng ba ts'ebetso ea theko ea phetisetso. Mefuta ea ho tiisa e ka khethoa ho latela maemo a fapaneng a mosebetsi. E loketse lihlopha tse mahareng le tse kholo tsa tlhahiso ea inthanete e tsoelang pele kapa tlhahiso ea ho e nchafatsa.

PONTS'O MOTLATSI