Mekhahlelo ea Lihlahisoa

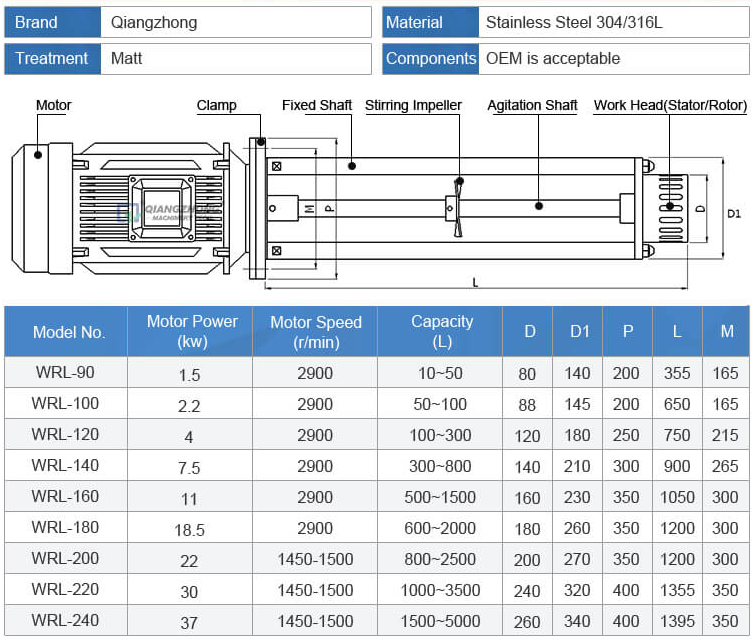

Sesebelisoa sena se ka hlophisoa ho latela lisebelisoa tsa moreki ho fihlela litlhoko tsa ts'ebetso joalo ka ho batla viscosity e kholo, ts'ebetso e ntlafalitsoeng ea homogenization, lisebelisoa tse hlokolosi tsa mocheso le litlhoko tse ling

SEBOPEHO SEhlahisoa

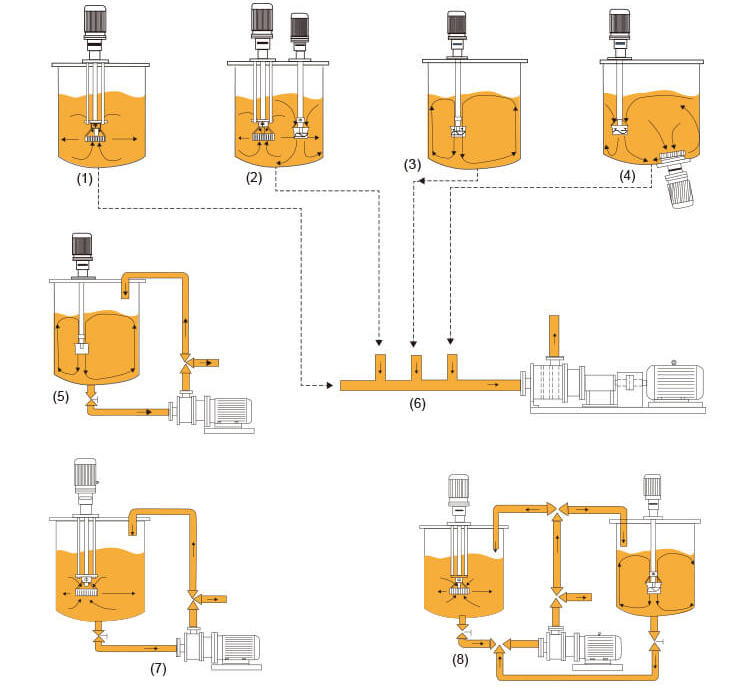

Emulsifier e sebetsa ka lisebelisoa tsa rotor tse lebelo le gear ea stator ho emulsify ka botlalo le ka potlako homogenize le ho hasanya motsoako ka sejaneng. E sebelisoa haholo lijong tsa lebese, seno sa bio-meriana, lik'hemik'hale tse ntle, 'mala le liindasteri tse ling ho ntlafatsa tšebetso ea tlhahiso le boleng ba tlhaho. E sebetsa haholo bakeng sa ts'ebeliso ea lisebelisoa tse kang CMC, marenene le phofshoana tse thata ho qhala.

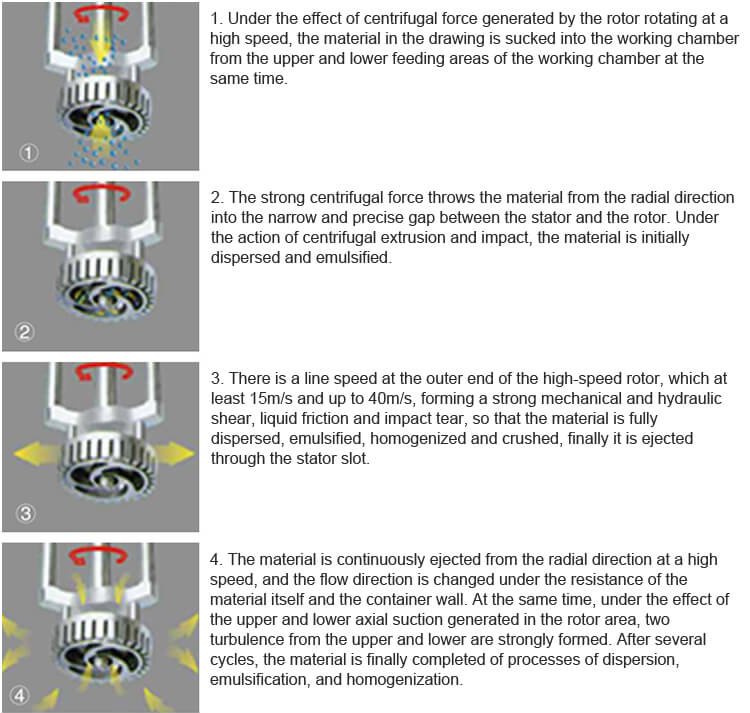

Ho sebetsa Molao-motheo

Mochini o kopane ka sebopeho, o monyane ka boholo, o bobebe ka boima, o sebetsa habonolo, o tlase ka lerata ebile o tsitsitse ts'ebetsong. Tšobotsi ea eona e kholo ke hore ha e sila thepa tlhahiso, 'me e kopanya ho kuta ka lebelo le phahameng, ho kopanya, ho hasanya le ho kopanya homogenizing.

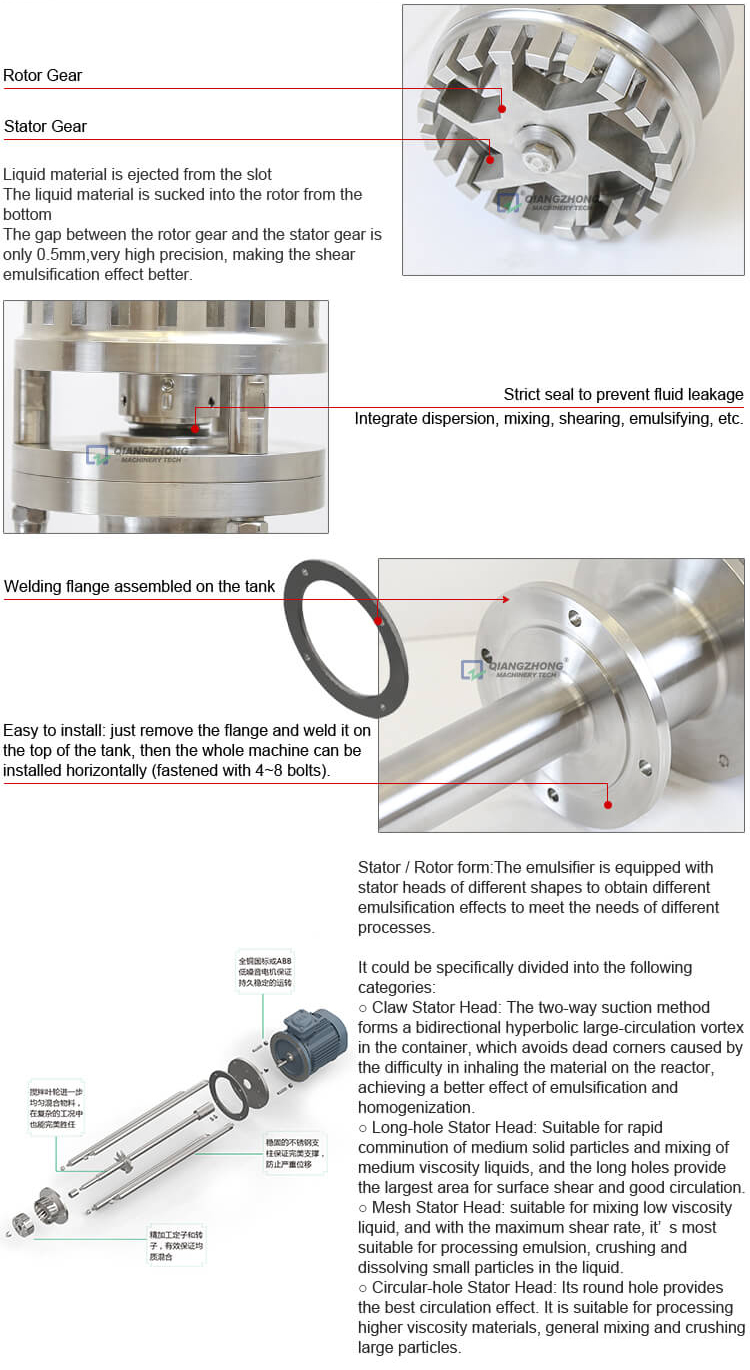

Hlooho ea ho kuta e amohela mofuta oa claw le mokhoa oa ho hula o habeli, o qoba li-angles tse shoeleng le li-eddies tse bakoang ke bothata ba ho hema lintho tse kaholimo. Lebelo le potolohang ka lebelo le phahameng le hlahisa lebotho le matla la ho kuta le etsang hore thepa e robehe ka mokhoa o fetelletseng molemong o moqotetsane, o nepahetseng lipakeng tsa stator le male rotor. Boitsebiso bona bo entsoe ka centrifugal extrusion, tšusumetso le tse ling tse joalo, ka hona li qhalakantsoe ka ho lekana, li tsoakane ebile li emulsified.

Tlhokomeliso: Haeba mochini o sebelisoa ka lephaka kapa ka setsing se nang le khatello, ho hlokahala tiiso e 'ngoe ea mochini.

Ts'ebetso e Shebiloeng ea Shear e Phahameng

Pontšo ea lihlahisoa

MOSEBETSI SEHLOHO SEHLOHO

Mefuta e Tloaelehileng ea Sebopeho

Ho latela litšobotsi tsa lisebelisoa le litlhoko tsa ts'ebetso ea mosebelisi, re tla khetha mofuta o nepahetseng oa sebopeho le lebelo.

Motswako And Collocation