Tanka ea Emulsification ea motlakase o futhumatsang motlakase

Re khetheha ho etsa lijo le thepa ea bongaka, 'me re u tseba betere! E sebelisoa haholo lijong, lino tse tahang, meriana, lik'hemik'hale tsa letsatsi le letsatsi, peterole le indasteri ea lik'hemik'hale

TLHAHISO MEKHOA

SEBOPEHO SEhlahisoa

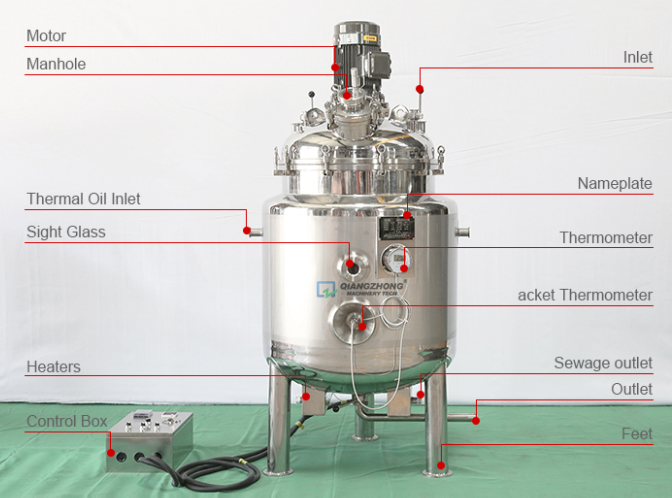

Tanka ea emulsification ke sesebelisoa se tsoetseng pele se ka kopanyang, emulsily, homogenize, qhala, silakanya lisebelisoa tsa lijo, meriana, lik'hemik'hale le tse ling. E ka etsa thepa e le 'ngoe kapa ho feta (wateroluble solid phase, liquid fluid, jelly, and etc.) e qhibiliha karolong e' ngoe ea mokelikeli ebe e ba etsa emulsion e batlang e tsitsitse. Ha o sebetsa, hlooho ea mosebetsi e lahlela thepa bohareng ba male rotor ka lebelo le phahameng, lisebelisoa tse fetang sebakeng sa leino la stator, mme qetellong li fihlela sepheo sa emulsification ka matla a ho kuta, ho thulana le ho pshatla lipakeng tsa male rotor le stator. E sebelisoa haholo bakeng sa ho sebetsana le oli, phofo, tsoekere joalo-joalo. Hape e ka emulsify le ho kopanya lihlahisoa tse tala tsa liaparo tse ling, pente, haholo-holo tse ling tse thata-qhibilihang ka har'a colloidal additives, tse kang CMC. Chelete ea xanthan.

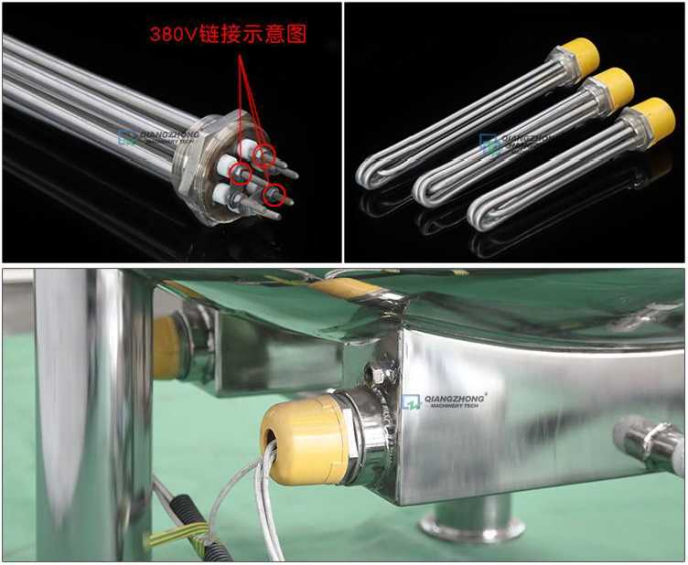

Bontša mocheso oa kahare oa motlakase

Melemo ea khokahano e khethehileng ea li-heaters:

1.Easy ho kenya heaters, ha ho hlokahale khethehileng play loading le unloading lisebelisoa.

Li-heaters li tlatsitsoe ka botlalo ka 'meleng oa tanka, ho netefatsa ho sebetsa hantle haholo ha ho futhumatsa.

3) fokotsa haholo litšenyehelo tsa ts'ebeliso le ho boloka matla.

MOLAO-MOTHEO OA HO SEBETSA

Hlooho ea mosebetsi e matlafatsang ea centrifugal e ka hlahisa matla a maholo a ho rotary mosebetsing, a potoloha thepa e kaholimo ho male rotor ho e anya, ebe o e akhela ho stator ka lebelo le phahameng. Kamora ho kuta ka lebelo le phahameng, ho thulana le ho sithabetsoa lipakeng tsa stator le male rotor, lisebelisoa li bokella le ho fafatsa ka ntle. Ka nako e ts'oanang, matla a potolohang a pherekano a tlase a tanka a fetoha matla a ho ea holimo le tlase, e le hore lisebelisoa tse ka tankeng li tsoakane ka mokhoa o ts'oanang ho thibela phofo hore e se ke ea kopana bokaholimo ba metsi ho fihlela sepheo sa hydration emulsification .

Hlooho ea mosebetsi e matlafatsang ea centrifugal e ka hlahisa matla a maholo a ho rotary mosebetsing, a potoloha thepa e kaholimo ho male rotor ho e anya, ebe o e akhela ho stator ka lebelo le phahameng. Kamora ho kuta ka lebelo le phahameng, ho thulana le ho sithabetsoa lipakeng tsa stator le male rotor, lisebelisoa li bokella le ho fafatsa ka ntle. Pipeline high-shear emulsifier e na le lihlopha tsa 1-3 tsa li-stators tse ngata tse koahelang lintho tse ngata le li-rotor n. Rotors potoloha ka lebelo le phahameng tlas'a khanna ea dilenaneo ho hlahisa matla axial fire, 'me thepa ea ananelang ka cavity, thepa botjha ha thepa thulaganyou e. Lisebelisoa li qhalakane, li kuta, li emulsified ka nako e khuts'oane ka ho fetesisa, mme qetellong re fumana lihlahisoa tse ntle le tsa nako e telele tse tsitsitseng. Emulsifier e nang le lebelo le holimo e ka tsamaisa sekhahla se le seng kapa tse 'maloa ka mokhoa o nepahetseng, ka mokhoa o ts'oanang, ha ka kakaretso mekhahlelo e sa lumellane. Ka sekhahla se phahameng sa shear se hlahisoang ke lebelo le phahameng la rotor le matla a phahameng a kinetic a tlisoang ke phello e phahameng ea maqhubu, lisebelisoa tse lekhalong le moqotetsane oa rotor le stator li qobelloa ke shear e matla ea mochini le ea haeteroliki, extrusion ea centrifugal, mokelikeli oa mokelikeli o mokelikeli , tshusumetso ya meokho le moferefere le litlamorao tse ling tse felletseng. Seo se etsa hore mohato o tiileng o sa lumellaneng, mohato oa mokelikeli le mochini oa khase hanghang o homogenized, o qhalakantsoeng le ho emulsified tlasa ketso e kopaneng ea mahlale a holileng a lekanang le bongata ba litlatsetso. Qetellong lihlahisoa tse tsitsitseng le tsa boleng bo holimo lia fumaneha kamora makhetlo a mangata a maqhubu a phahameng.